Loom & Textile Weaving Process

One of my fascinations with weaving is understanding how the loom works and the design process.

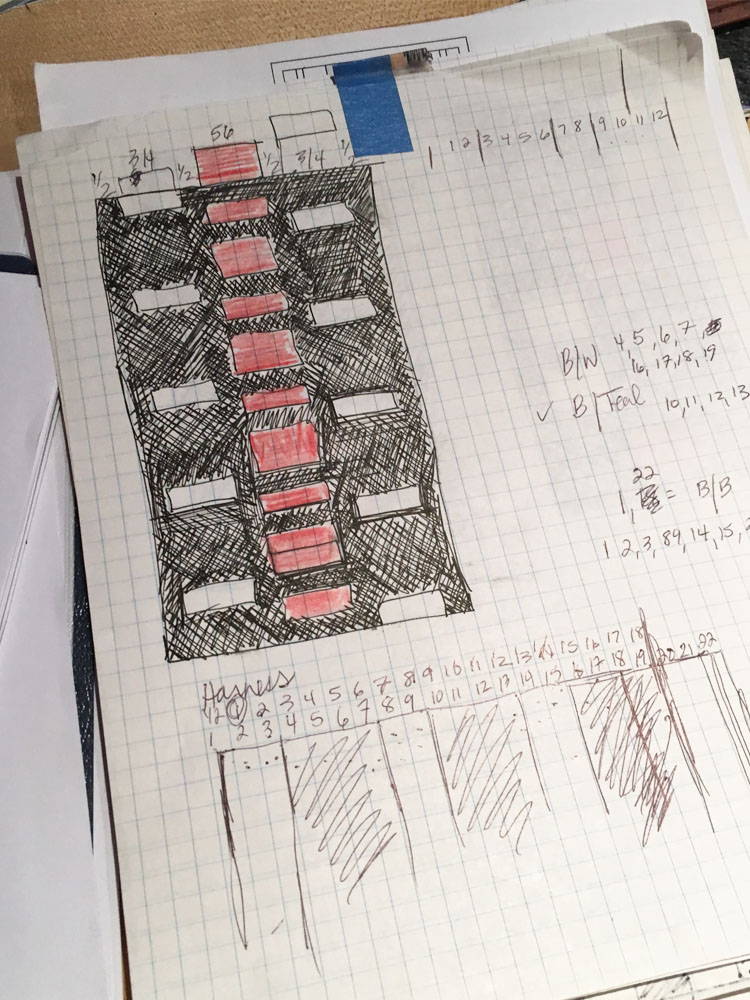

My first step is to sketch out ideas on graph paper. Each design I create on paper is then carefully translated to the loom. Once the design is determined the loom has to be “tied up” specifically for that design. Once the tie up has been completed, we can then start the warping process.

Warping consists of wrapping the warp threads around the back beam of the loom in sections using a warp box. Each section is then pulled through and individual heddle (eye) on a specific harness (2-8 harnesses) and then pulled through the reed. Once this process is complete it is then tied to the front beam. The warping process is now done.

Using a shuttle, I send the weft material through the warp strings by pushing down on the peddles which creates a shaft (opening) for the weft to be placed. The weft is beaten into place using the over-head beater. Weaving repeats over and over from right to left until rug is complete. This creates the body of the rug, while following the pattern you have designed.

Once the rug has been completed it has to then be cut off the loom and the finishing process begins. Fringe ends are tied, or ends can be bound to create a clean finish.

Tie-up and Warping of the loom take the most time, and are the most tedious. Weaving the rug in my opinion is the “relaxing” part. That is where you get to see the fruits of your labor right before your eyes!

Custom Orders Welcomed

I produce custom pieces on request. Please contact me and we can discuss and plan the design, size, colors and use. Particular colors might take some time to work into the schedule of loom time but I do my best to meet all requests.

I love to see my clients excited about their vision coming to life!

Weaving Care Instructions

Rugs are Machine Washable in cold water only. Line Dry. Front loaders tend to be the best. They can be shook out, as well as, vacuumed.